2026 How to Choose Electric Ball Valves for Your System?

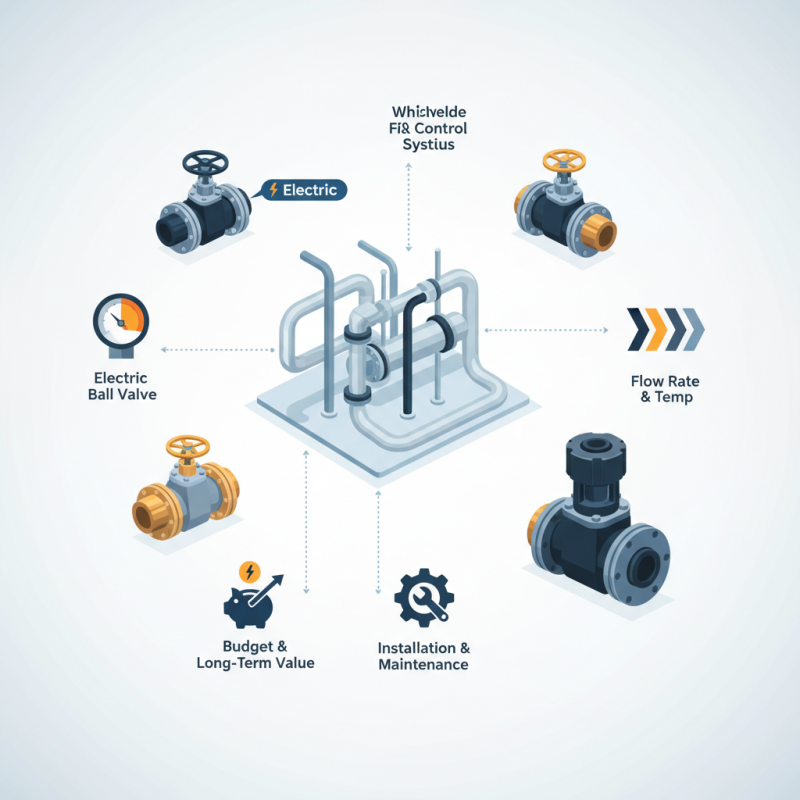

Choosing the right Electric Ball Valves for your system can be a daunting task. These valves play a crucial role in controlling fluid flows. Their efficiency impacts the overall performance of your system. With various options available on the market, making a well-informed decision is essential.

Many factors should guide your selection. For instance, the size of the valve greatly affects flow rates. You must also consider the operating pressure and temperature. Electric Ball Valves come in different materials, each suited for specific applications. It's important to align these features with your system's requirements.

However, even the best Electric Ball Valves can have drawbacks. Installation can be complex, and maintenance may be required more often than expected. Evaluating your long-term needs and budget is vital. Don't overlook the importance of quality over price. Poor choices can lead to significant issues down the line. Building a reliable system demands careful thought and understanding.

Understanding Electric Ball Valves: Key Features and Benefits

Electric ball valves offer numerous advantages for modern systems. These valves provide reliable and efficient control of fluid flow. They are designed for quick operation, usually completing a full open or close in just a few seconds. This feature is essential for processes that require prompt adjustments.

Key features of electric ball valves include precision control and automation compatibility. Many systems can integrate these valves with controllers for programmable operation. This allows for seamless adjustments without manual intervention. Additionally, they improve safety by minimizing the risk of leaks. The electric actuation reduces the need for complex mechanical linkages.

However, choosing the right valve can be challenging. Not all models are suitable for high-pressure applications. Some may not withstand extreme temperatures. Users must evaluate their specific needs carefully. It's vital to consider both the environment and the medium being controlled. Overlooking these details can lead to operational failures. Reflection on system requirements is crucial.

Factors to Consider When Selecting Electric Ball Valves for Your System

Choosing electric ball valves for your system requires careful consideration. Start by assessing your application’s specific needs. Think about fluid types, pressure ranges, and temperatures. This will determine the valve materials. For instance, corrosive liquids may require special coatings or materials. The size of the valve also matters. Ensure it fits your pipeline perfectly to avoid leaks.

Next, consider the control options. Electric ball valves come with different actuator types. The choice between on-off or modulating control impacts your system's flexibility. Some systems may benefit from remote operation. Others may need manual overrides. Evaluate how these factors align with your operational requirements.

Don’t forget the importance of reliability and maintenance. Look for valves that are easy to service. Complex designs can lead to unforeseen issues. Check for compatibility with existing systems. An incompatibility may lead to unexpected costs in the future. Reflect on your choices and their long-term implications to ensure a sound investment.

Comparative Analysis: Different Types of Electric Ball Valves in the Market

When selecting electric ball valves, understanding the types available is crucial. A comparative analysis reveals that the two primary types are on-off and modulating valves. On-off valves are simpler. They serve to fully open or close the flow, typically used in applications demanding high reliability. Modulating valves allow for variable flow control. They are perfect for applications requiring precise flow rates.

A market report from 2022 indicates that 40% of industrial applications favor modulating valves due to their flexibility. However, not all systems require such precision. Many engineers find on-off valves easier to maintain. The choice depends on system needs and expected performance. A single mistake in selection can lead to inefficiencies. Choosing the wrong valve affects operational cost and system performance.

Users often overlook critical specifications like the valve's pressure rating and flow characteristics. In some case studies, failures occurred because of these oversights. Understand the environment too; chemical compatibility matters. Just because a valve is electric doesn't mean it's suitable for all situations. Ultimately, ensuring the correct fit for your system is fundamental.

Comparative Analysis of Different Types of Electric Ball Valves

Industry Standards and Certifications for Electric Ball Valves: What to Know

When selecting electric ball valves, industry standards and certifications play a crucial role. These factors ensure safety, reliability, and performance. Common certifications include ISO, CE, and UL. Each standard focuses on different aspects, such as manufacturing quality and safety practices. Understanding these certifications helps in making informed decisions.

It's important to note that not all manufacturers adhere to these standards. Some may skip essential testing to cut costs. This could lead to potential failures in your system. Make sure to verify that the product meets required standards. This verification can prevent costly future repairs and ensure longevity.

Additionally, the market is cluttered with options. Browsing through countless variations can be overwhelming. Not every valve is suitable for every application. An unfit choice can impact efficiency. Researching applicable industry standards provides clarity. Compare various models based on these benchmarks. This approach narrows down your selection process.

Performance Metrics: Evaluating Electric Ball Valves for Efficiency and Durability

When evaluating electric ball valves, performance metrics play a critical role. Efficiency is key; you need valves that respond quickly. Look for clear specifications on operation speed. Durability matters, too. A valve must withstand harsh conditions without frequent replacements.

Inspecting pressure ratings and temperature ranges can help gauge durability. Check materials used in construction. Are they corrosion-resistant? This ensures longevity. Examine the maintenance requirements as well. Some valves need regular checks, while others are low-maintenance.

Another aspect is energy consumption. An efficient valve can reduce operating costs significantly. Verify the power requirements and how they fit into your system’s overall energy usage. Lastly, while features are appealing, they should align with your specific needs. Overcomplicating the choice can lead to issues down the line. Consider real-life applications and potential shortcomings in functionality before making a decision.