2026 How to Choose the Best Stainless Steel Wire Mesh?

Choosing the right stainless steel wire mesh is crucial for various applications. This material is known for its strength and durability. However, not all stainless steel wire mesh is created equal. Different grades and specifications exist, and selecting one can be daunting.

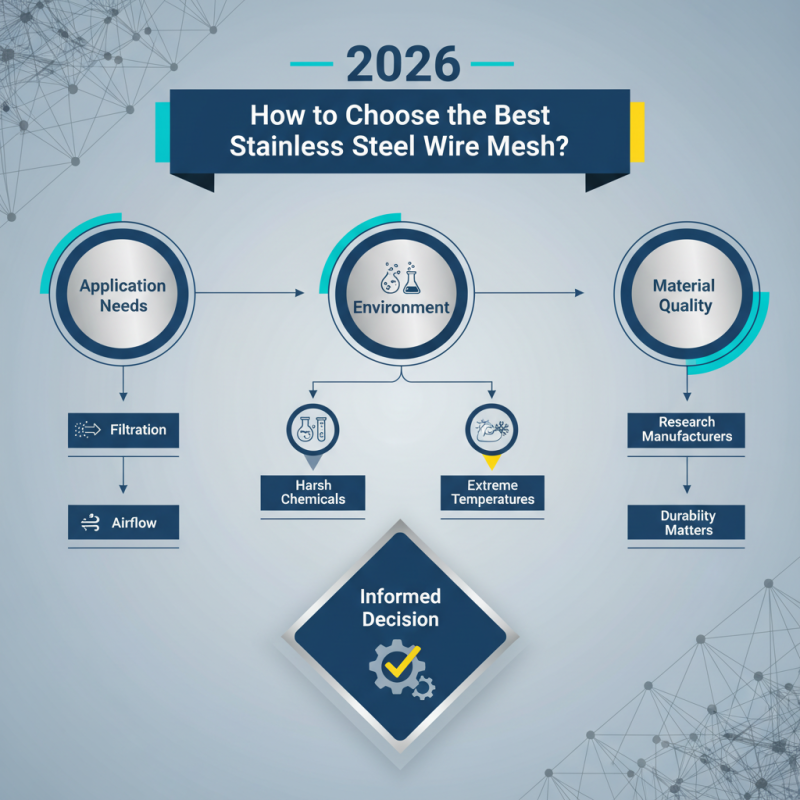

Consider the mesh size. Smaller openings provide better filtration, while larger ones allow for more airflow. Think about the environment too. Will it be exposed to harsh chemicals or extreme temperatures? The right choice can greatly impact the longevity and effectiveness of the mesh. Yet, many overlook these details.

Quality also varies across manufacturers. Some may promise durability but fall short in real-world conditions. Doing thorough research is essential to avoid common pitfalls. Reflect on what you need from your stainless steel wire mesh. Taking the time to assess your specific requirements can lead you to a better and more informed decision.

Factors to Consider When Choosing Stainless Steel Wire Mesh

Choosing the right stainless steel wire mesh is crucial for various applications. When selecting a wire mesh, several factors come into play. First, consider the mesh’s purpose. Different applications require different specifications. Are you using it for filtration, security, or construction? Each use dictates certain requirements.

Wire diameter is another key factor. Thicker wires provide more strength, but they may reduce flexibility. Balance is essential. A finer mesh can filter small particles but may not hold up under heavy loads. Consider the environment too. Will it face corrosion? Choosing a suitable grade of stainless steel is vital for durability.

**Tip**: Always check the mesh’s weave pattern. A tighter weave can offer better protection for smaller items. Testing with a sample can help assess if it meets your needs. Look for inconsistencies in the product. An imperfect mesh can cause unexpected issues down the line. Adjust and reflect on the initial choice, as this can impact overall performance significantly.

Factors to Consider When Choosing Stainless Steel Wire Mesh

Types of Stainless Steel Wire Mesh and Their Applications

When selecting stainless steel wire mesh, understanding the types available is crucial. Various types offer different properties and applications. For example, welded wire mesh is commonly used in construction. It provides structural support and stability. On the other hand, woven wire mesh is versatile, found in filters and architectural elements. A report from the Stainless Steel Wire Mesh Association shows that woven mesh comprises about 43% of market share. This highlights its popularity in various industries.

Another type, decorative mesh, serves aesthetic purposes. It often finds application in interior designs. This type can incorporate intricate patterns. Its demand is growing, driven by trends in modern architecture. Wire mesh has also found its way into the food processing industry. High corrosion resistance makes it ideal for equipment and storage solutions. According to a report from Global Industry Analysts, the market for stainless steel wire mesh is projected to grow by 8% per year through 2026.

When exploring these options, the finer details matter. Not all stainless steel is the same. Different grades and finishes can affect performance. It's essential to consider the specific needs of each application. Long-term exposure to harsh chemicals may require higher-grade materials. Regularly assessing your choice is vital to ensure optimal use. Each application brings unique challenges and learning opportunities. This complexity makes careful selection even more important.

Mesh Size and Wire Diameter: Finding the Right Balance

When selecting stainless steel wire mesh, mesh size and wire diameter play crucial roles. The right balance between the two is important for optimal performance. A finer mesh size provides better filtration but may lead to reduced flow rates. Conversely, a coarser mesh can handle higher volumes but might not filter out smaller particles effectively. According to the Stainless Steel Wire Cloth Association (SSWCA), selecting the right mesh can enhance efficiency by up to 30% in industrial applications.

Wire diameter directly affects the strength and durability of the mesh. Thicker wires are sturdier and can withstand harsher conditions. However, they also reduce the effective opening size. A recent report highlighted that using wire diameters of 0.5 mm or thicker increased structural stability by 25%. It’s essential to evaluate the intended use. Overly thick wires may compromise filtration efficiency, while too fine wires could break under pressure.

This balance is often overlooked, leading to suboptimal choices. A study by the Wire Mesh Institute revealed that 40% of users reported performance issues due to mismatched specifications. Proper testing and assessment based on individual needs are necessary. Consider your specific application and environment before finalizing your choice. Mistakes can lead to costly replacements and downtime.

Corrosion Resistance and Durability: Key Attributes

When selecting stainless steel wire mesh, corrosion resistance and durability rank high on the priority list. Corrosion resistance is essential in many industries. Reports show that stainless steel can last anywhere from 10 to 100 years, depending on its grade and environment. Generally, higher chromium and nickel contents lead to better corrosion resistance. For instance, a grade like 316 may provide enhanced protection against saline environments, making it ideal for marine applications.

Tips for choosing the right wire mesh: always consider the environment where the mesh will be used. If it’s exposed to corrosive elements, prioritize higher grade materials. Moreover, conducting a thorough inspection of the mesh’s performance data can reveal its longevity. Review specific corrosion testing results, as they often indicate resistance levels against various chemicals.

Durability is another crucial factor. Some meshes may appear strong but can fail under stress. Check tensile strength ratings and elongation percentages. Many industry standards suggest that a mesh with at least 50,000 psi yield strength is more reliable. However, not every application requires such high thresholds. Always evaluate your specific needs and avoid over-engineering, which might lead to unnecessary costs.

Cost-Effectiveness: Evaluating Quality vs. Price

When evaluating the cost-effectiveness of stainless steel wire mesh, balancing quality and price is crucial. A recent industry report from MarketsandMarkets indicates that the global stainless steel wire mesh market is projected to reach $3.3 billion by 2025. This growth emphasizes the demand for quality materials, underscoring the importance of evaluating not just the price but also the material's durability and application.

Choosing the right mesh involves considering various factors. The thickness, weave type, and corrosion resistance all play a role in the overall performance. A mesh with a finer weave might be more expensive but can offer superior filtration. Conversely, a thicker wire might be lower in price but compromise on flexibility. According to the Mesh Manufacturers Association, about 25% of lower-priced options fail to meet industry standards, leading to potential maintenance issues. Remember, purchasing solely based on price can lead to long-term costs due to replacements.

Additionally, consider the source and manufacturing process of the wire mesh. Different producers may use varying quality control measures. A mesh made from recycled steel can reduce costs, but it may also perform inconsistently. Balancing these aspects is not straightforward. Weighing the upfront price against potential longevity and efficiency can be challenging yet essential in making an informed choice.